- sovasolar_admin

- Dec 26, 2024

- solar

- 0 Comments

Solar panels are at the heart of the renewable energy revolution, converting sunlight into electricity and paving the way for a sustainable future. But have you ever wondered how these ingenious devices are made? As one of the best solar panel manufacturers in Maharashtra, Sova Solar is here to demystify the manufacturing process.

Step 1: Creating the Solar Cells

Solar panels are made up of numerous solar cells, and their creation is the first and most critical step. Here’s how it works:

- Purifying Silicon: The process begins with silicon, a key material in solar cells. Raw silicon is purified and melted to form high-quality silicon ingots.

- Shaping Ingots: These ingots are sliced into thin wafers, which will form the basis of the solar cells.

- Doping: The wafers are then treated with phosphorus or boron to create a positive or negative charge, enabling the photovoltaic effect.

Step 2: Assembling the Solar Cells

- Adding Conductors: Thin lines of conductive materials are printed onto the surface of the wafers to create the grid-like pattern seen on solar panels.

- Anti-Reflective Coating: To maximize sunlight absorption, the wafers are coated with an anti-reflective material.

- Stringing Cells Together: The individual cells are connected to form a solar module capable of generating usable electricity.

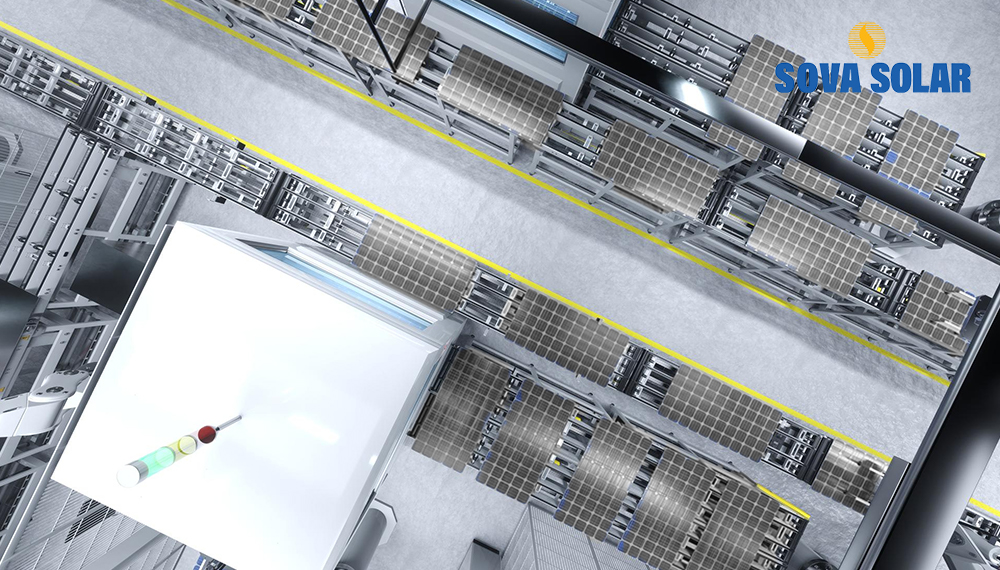

Step 3: Creating the Panel

- Encapsulation: The solar cells are encapsulated between protective layers to shield them from moisture and physical damage.

- Adding Glass: A tempered glass layer is added to the front of the panel to provide durability and transparency.

- Framing: An aluminum frame is attached for structural support and easy installation.

Step 4: Quality Testing

Before reaching the market, solar panels undergo rigorous testing to ensure performance, durability, and efficiency. Tests include:

- Thermal Cycling: Panels are exposed to extreme temperature variations.

- Load Testing: Simulated wind and snow loads ensure structural integrity.

- Efficiency Testing: Panels are evaluated to confirm their energy conversion rates.

Step 5: Packaging and Distribution

Once the panels pass quality checks, they are carefully packaged and shipped to distributors and customers worldwide.

Why Choose the Best Solar Panel Manufacturers in Maharashtra?

Choosing a reputable manufacturer ensures you get high-quality panels that are efficient, durable, and backed by excellent support. At Sova Solar, we take pride in combining cutting-edge technology with a commitment to sustainability, making us one of the best solar panel manufacturers in Maharashtra.

Conclusion

Understanding how solar panels are manufactured highlights the intricate engineering that goes into harnessing the power of the sun. From silicon wafers to fully assembled panels, every step is a testament to innovation and precision. When you choose Sova Solar, you’re choosing expertise and reliability for your renewable energy journey.

Looking to go solar? Stay updated with our blog for more insights into the world of solar energy!